Our attention to detail, detailed knowledge of our capabilities results in a seamless process to meet your needs.

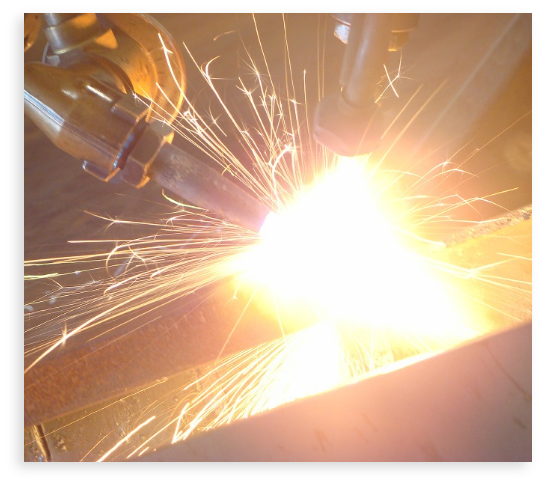

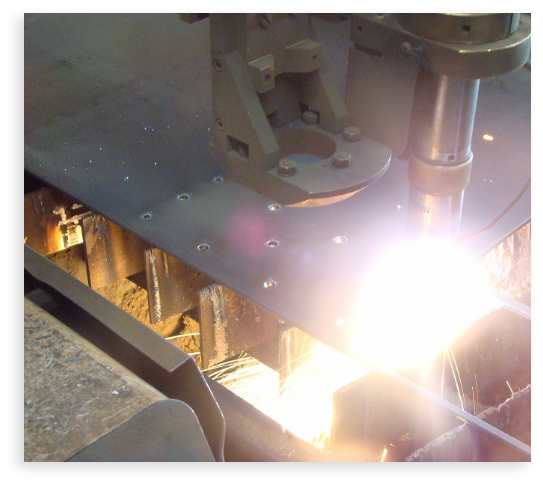

Plasma cutting directs a jet of ionised gas at temperatures above 20,000 degrees which in turn melts and expels the material from the cut.

We offer a range of drilling and bevelling solutions, through two methods.

Oxy-Fuel Cutting is thermal cutting process that uses a high intensity of oxygen plus LPG for fuel. The large heat application during cutting is what increases the tolerances.

Laser cutting is a thermal process where the laser beam is produced from two types of power sources, either C02 or Fibre. Both are a high precision method of cutting.

We offer a range of bevelling solutions through two methods.

Primero stocks a large range of material sourced from our trusted partners throughout the world. We’ve worked hard to match our extensive stock holding to suit our machines and customer needs to give you the products and services you can consistently rely on.

Also commonly known as: G250, G300, G350. Manufactured to either AS/NZ 3678 or AS/NZ 1594 standards or equivalent European Standard (EN10025).

Has a higher yield than conventional steel. We stock an extensive range of G450 and/or equivalent JIS grade as well as Wel-Ten780 (Nippon Steel produced) 780 tensile strength steel.

An abrasion resistant plate measured by way of Brunell Hardness that has 2-5times scratching abrasion resistant of mild steel.